In the high-power sophisticated electrical system, the safety of men and equipment needs a high level of attention. In industries and domestic buildings, many electrical protection devices are used; these devices protect humans and equipment from shock and damage.

There are a lot of devices that are made for my protection of me, which work on electrical systems. Along with this, many devices are also made to protect your highly sophisticated and modern equipment from the hazards of high powers.

Programmable logic controllers (PLCs) are top of the list in these devices. The contactor is also a protection device for those types of equipment. What is a contactor? You will find out in this article.

What is Contactor?

Suppose you know about the function of a switch. You can easily understand the contactor. The primary purpose of the contactor also is switching. But contactor switching and regular switching make the contactor a unique device. By using electromagnetic control, a contactor can make or break an electrical circuit or switch on or off a device. Contactors will help your electrical system in the safety of sophisticated electrical devices like Programmable Logic control.

There are mainly two types of devices that work on electromagnetics. The first is the relay, and the second is the contactor. But the relay is used for low current applications, whereas the contactor is used for high current applications. In this high-current application, controlling three-phase motors is at the top of the list.

A contactor can switch on or off the high power/ high current motors using twelve or, in some cases, twenty-four volts, which are coming from PLCs. When PLC sends a command to switch on the motor, from PLC, twelve volts flow towards the contactor. With the help of these twelve volts, the contactor switch on the high current motor. This high current is isolated from PLC via a contactor.

A contactor is an electrical component used to control the flow of electricity in an electrical circuit. Essentially, it is a switch operated by an electromagnet, allowing it to open or close the circuit as needed. Contactors are commonly used in larger electrical systems, such as industrial equipment, HVAC systems, and other types of machinery.

They can control the power supply to motors, lights, and other electrical devices and are designed to handle high current loads with minimal energy loss. Contactors are typically made up of a coil, a set of contacts, and a contact carrier, forming a sturdy, reliable mechanism for controlling electrical circuits. They are available in a range of sizes and configurations to suit different types of applications. They can be customized with additional features like auxiliary contacts and overload protection to meet specific needs. Overall, contractors are an essential component in many electrical systems, providing reliable and efficient control over the flow of electricity.

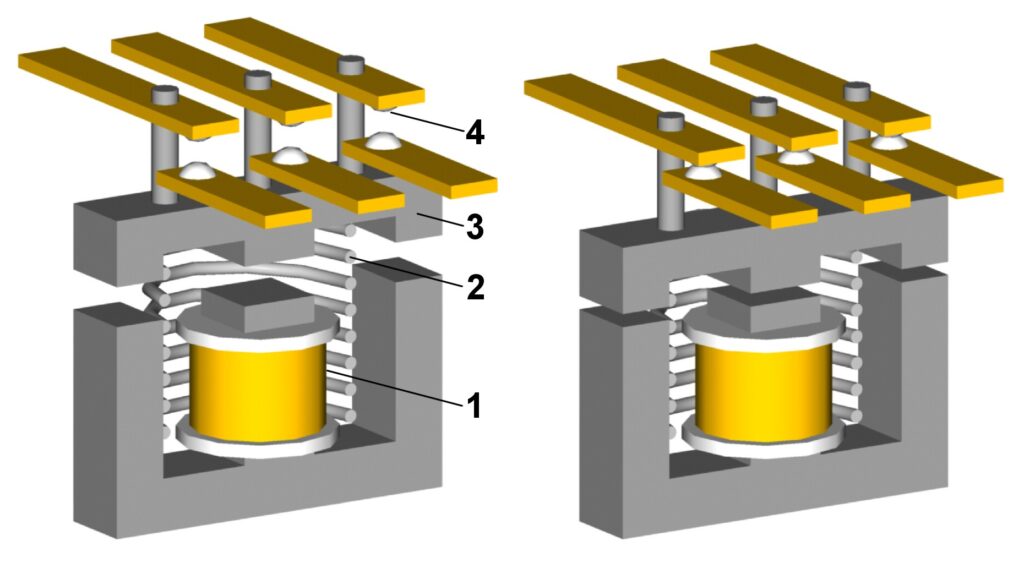

Construction and working of contactor

After knowing what a contactor is, you will learn about the basic construction of contactors in this section. The contactor which is available in the market is of different types. These types give you to choose from them according to your need and application.

Auxiliary contacts on a spring between the coil and the movable core may be normally open or closed. The primary contacts control the light current loads, which include relays, timers, relay coils, and many other components of control circuits. However, regardless of its type, some things are ever-contactor every day. These parts are listed below:

- Contacts

- EM coil

- Body

Following is the detail of every part of a contactor:

Contacts

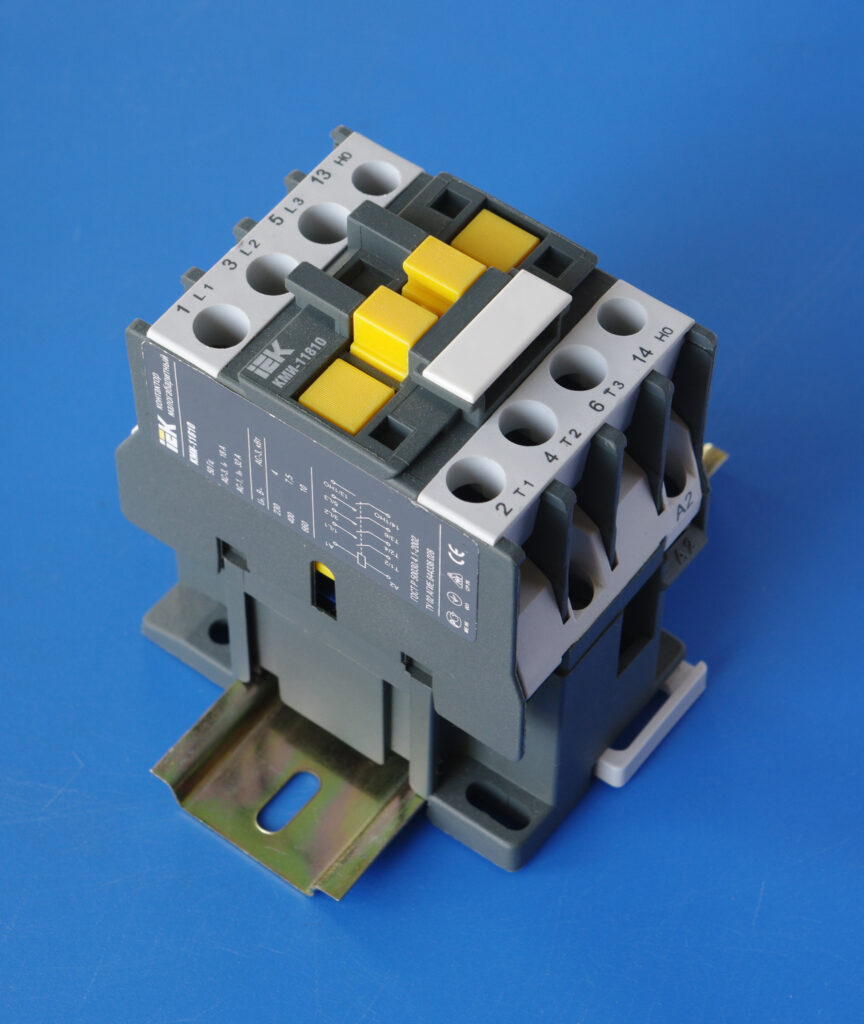

Contacts are the central parts situated on the mainframe or body of the contactor. Some contacts have eight contacts on it, and some have six contacts. The contactors with eight contacts on their frame/body are used for the three-phase supply. And six contact contractors are used for only single-phase supplies. These contacts are used to take instruction from the PLC and make or break the connection to the load. All the contactors contact has a specific purpose, and a name is given to each contact.

L1, L2, and L3

The contact’s name is L1, L2, and L3 on the one side of the contactor. This contactor side takes the mainline’s input power supply through a three-phase AC supply.

TI, T2, and T3

T1, T2, and T3 are mentioned on the second side of the contactor. This side of the contactor connects to the load, for example, a three-phase motor.

Auxiliary

These two contacts are used to give the PLC or control device feedback if the contactor works appropriately; this pin signals to the PLC about the proper functioning of the contactor. If the L1, L2, and L3 phases suffer from any fault, then this auxiliary contact did not give any feedback to the PLC. And in a result of this feedback PLC take further precautionary measure to reduce the risk of load damage.

Normally open or usually close contact

These contacts of the contactor are attached to the controlling device of PLC. These contacts are coming into the market in two forms. Normally open and usually close. A positive 12- or 24-volt supply is generated from the PLC for normally available contacts when the PLC commands the contactor to switch on the load. This energizes the EM coil, which connects L1, L2, and L3 with T1, T2, and T3. As a result, the motor will switch from the off position to the on position. When it is required to switch off the load, PLC stops supplying 24 volts.

In the resulting spring attached to the respective contact, pull back the contact and switch off the load. Because of the electromagnet field, the contactor stays in “ON” condition in contrast to the ordinarily closed contactor, where the PLC continuously supplies 12 or 24 volts. When switching off the load is required, the PLC machine stops the 24 volts supply. After the absence of the 24 volts dc supply, the springs pull back the contacts. As a result, the load will be off.

Body of a contactor

The body of the contactor is a frame that comprises all the elements, like an electromagnetic transformer, contacts, screws, etc. The other important thing mentioned in the body of a contactor is labeling. This labeling describes what a contactor is and the different parts of the contactor. In this generally, current and voltage rating is also mentioned, which is an essential marking. Without this marking, you cannot determine that contactor’s exact type and rating.

Conclusion

As a result of reading the article, you will be able to answer the following question: what is a contactor? It is an equipment safety device that isolates high current high voltage from entering the sophisticated controlling types of equipment like Programmable Logic Controllers.

FAQS

- Describe the workings of a contactor.

Designed for use with heavy motors, contactors control and reduce the arc produced when these currents are interrupted. The contacts are also set up with normally open and low current contacts.

- What are PLC contactors for?

When this occurs, the feedback contact will close, and a signal will be sent to the PLC input, signifying that the contactor has worked correctly. In addition to de-energizing the coil, the contact opens, and the motor will shut off when the stop switch is pressed.