Humidity chambers are also known as Humidity incubator. They are here to control over uncontrolled conditions. When it comes to environmental test chambers, humidity is perhaps one of the things that is most often misunderstood by people. This occurs as a result of the fact that the percentage of relative humidity changes depending on the temperature. The humidity chambers have been purpose-built to maintain an atmosphere that is consistently dry, which is essential for the development of both plants and animals. The digital temperature gauge and controller are responsible for accurately maintaining the temperature within a range of 5 degrees to 60 degrees Celsius, and they perform effectively.

The most advanced temperature and humidity chambers provide consumers the ability to precisely adjust the conditions in order to conform to various testing requirements. You are able to assess the efficiency of your products and set standards for the customers’ expectations.

There has been much discussion over the efficacy of humidity chambers despite the fact that they have been in use for quite some time. The fact of the matter is that they most likely are effective to some degree. However, the primary reason why they are used is due to the very high cost associated with doing so. This is due to the fact that not only do they need a large amount of equipment, but they also demand a large amount of room. Humidity chambers manufacturers offer products that has characteristics such as the humidity chambers’ capacity to replicate a wide range of temperature and relative humidity (RH) conditions, ease of operation of the chamber itself, and the ability to perform operations from both the controller and the computer.

How do you regulate the humidity in the incubator?

The majority of incubators are equipped with a straightforward method for controlling the degree of humidity. The majority of these techniques involve pouring water into the incubator’s built-in water trays located at the base of the device. Because of this, the more trays you fill, the greater the amount of moisture that will be present in the air. They may contain multiple separate trays. Any dish may function as a humidity tray in an incubator.

Getting Ready to Use the Incubator

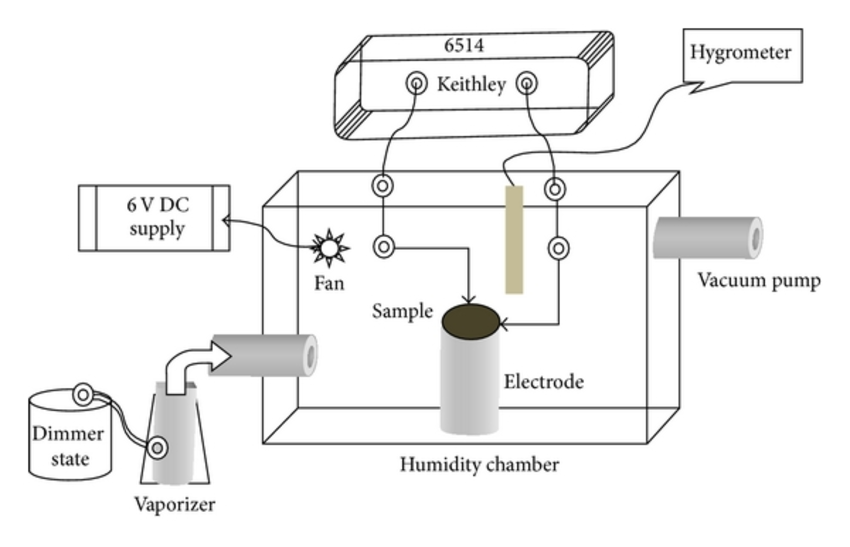

The temperature and humidity levels in the incubator need to be brought under control before anything can be placed inside. Turn on the incubator once you have added water to the reservoir according to the instructions provided for your specific type of incubator. For an incubator with forced air, set the temperature to 100 degrees Fahrenheit, and for an incubator with still air, set the temperature to 102 degrees. Wait until the temperature has reached a steady state before reading the amount of humidity shown on your hygrometer. The humidity level need to be anywhere between 55 and 60 percent. In the majority of cases, maintaining an adequate level of humidity during the incubation period of 21 days requires just the consistent addition of water to the water tray.

Purpose of Humidity Chamber

Humidity temperature chambers are used to simulate environmental conditions inside of a controlled cabinet so that the impact of such variables may be evaluated on product samples. Before releasing their final goods, manufacturers of semiconductors, automobiles, cement, food, and pharmaceuticals put their samples through a “damp and heat test” in one of these chambers. Some of the uses for these chambers include “tropical exposure” and “damp and heat test.”

In addition, Humidity chambers manufacturers provide best quality customized services to the customers so that they may fulfil the varied requirements of a wide variety of markets and applications. The experts here are able to produce the user-required machine at a price that is fair in India, whether it requires a minor adjustment in the design or extra add-on fittings.